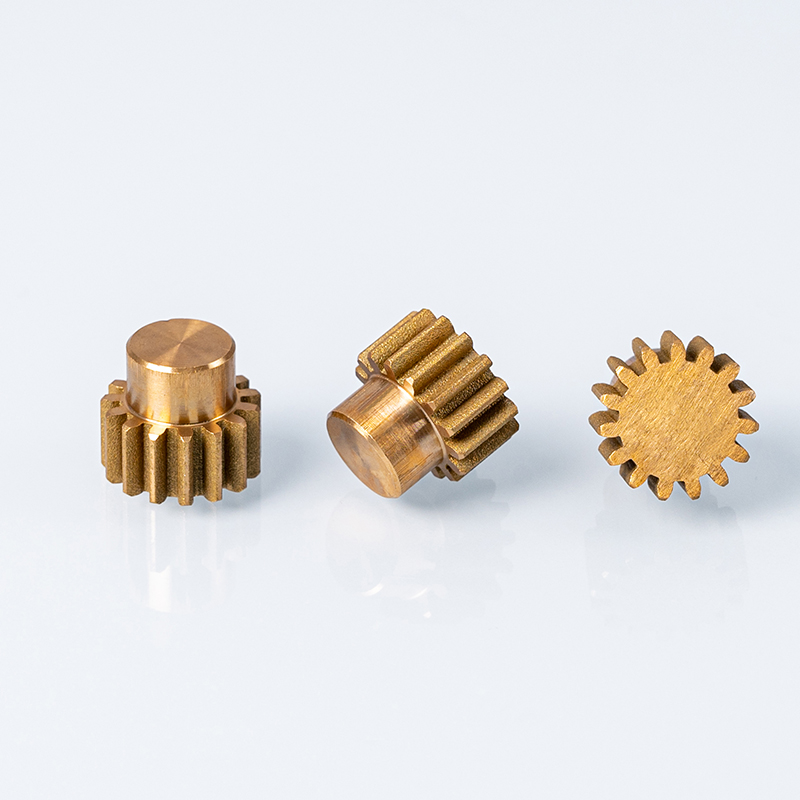

CNC machining ezingxenyeni zethusi for medical

Ukucaciswa kwezingxenye zemishini ye-CNC nge-Copper Material

I-Copper nayo ayinazibuthe futhi ayinanhlansi, okuyenza ifanelekele ukusetshenziswa emishinini yezokwelapha echayeka kumaza kagesi noma izinkundla ezinamandla kagesi. I-Copper iphinde imelane nokugqwala, okuyenza ibe ukukhetha okuhle emishinini yezokwelapha echayeka emanzini noma kolunye uketshezi. I-CNC machining yethusi ivumela ukukhiqizwa kwezingxenye eziyinkimbinkimbi, eziyinkimbinkimbi ngezinga eliphezulu lokunemba nokunemba. Izingxenye zethusi zingenziwa ngomshini ukuze zicacise imininingwane kanye nokubekezelelana, kuqinisekiswe ukuthi imishini yezokwelapha iphephile futhi iyasebenza.

1. I-Copper Material: C110 (99.9% Copper)

2. Inqubo: CNC Machining

3. Ukubekezelela: +/-0.01mm

4. Qeda: Yemvelo 5. Isicelo: Isetshenziswa ku-electronics, ugesi, ukukhanyisa nezinye izimboni.

Inzuzo ye-CNC machining Copper

I-CNC machining copper inikeza izinzuzo eziningi, njengokunemba okuphezulu nokunemba, isilinganiso esihle kakhulu samandla-kuya-isisindo, ukuguquguquka okuhle kwe-thermal kanye nogesi, ukwanda kokumelana nokugqwala uma kuqhathaniswa nezinye izinsimbi, ukuzinza kwe-dimensional phezu kwebanga elibanzi lokushisa, ukunciphisa isikhathi somshini ngenxa yokungasebenzi kahle kwayo kanye nokusebenziseka kalula.

1. Amandla aphakeme nokuqina - Ithusi liyinto ehlala isikhathi eside futhi likwazi ukumelana namazinga okushisa aphezulu, ukucindezela nokuguga. Lokhu kuyenza ibe yisinqumo esihle kakhulu sezinhlelo zokusebenza zemishini ye-CNC, njengoba ingasetshenziswa ezinhlelweni eziningi ezihlukahlukene futhi ikwazi ukumelana nobunzima bokuphindaphinda, ukusebenza kwemishini yokunemba okuphezulu.

2. I-thermal conductivity enhle kakhulu - I-Copper enhle kakhulu ye-thermal conductivity iyenza ilungele izinhlelo zokusebenza zemishini ye-CNC ezidinga ukusika nokumba ukunemba. Lokhu kuqinisekisa ukuthi umkhiqizo oqediwe uzoba nezinga eliphezulu lokunemba nokunemba.

3. I-high conductivity kagesi - Lesi sici senza ithusi libe yinto efanelekile yokusebenza kwemishini ye-CNC edinga izintambo zikagesi noma izingxenye.

4. Imali engabizi kakhulu - I-Copper ngokuvamile ayibizi kakhulu kunezinye izinsimbi, okwenza kube ukukhetha okuphelele kumaphrojekthi womshini we-CNC adinga inani elikhulu lezingxenye noma izingxenye.

5. Kulula ukusebenzisana - I-Copper iyinto elula ukusebenza ngayo, evumela ukukhiqizwa okusheshayo nokunemba okukhulu.

Indlela Ithusi ezingxenyeni zemishini ye-CNC

Izingxenye zethusi zomshini we-CNC zibandakanya ukusetshenziswa kwamathuluzi okusika ngokunemba njengezigayo zokugcina ukuze kukhishwe izinto ezisetshenziswayo ngokuya ngendlela ehleliwe. Ukuhlelwa komshini we-CNC kwenziwa ngesofthiwe ye-computer-aid design (CAD) bese idluliselwa emshinini ngekhodi ye-G, eyivumela ukuthi icubungule ukunyakaza ngakunye. Izingxenye zethusi zingabholwa, zigaywe noma ziphendulwe kuye ngohlelo lokusebenza. Uketshezi lwensimbi luvame ukusetshenziswa ngesikhathi sezinqubo zemishini ye-CNC, ikakhulukazi lapho usebenza nezinsimbi eziqinile njengethusi ezidinga ukugcotshwa okwengeziwe.

Izingxenye zethusi ze-CNC ziyinqubo yomshini yokusebenzisa imishini yekhompyutha elawulwa izinombolo (CNC) ukuze ilolonge izinto zethusi. I-Copper isetshenziswa ezinhlobonhlobo zezinhlelo zokusebenza ze-CNC ezifaka i-prototyping, isikhunta, izinto ezilungiswayo, nezingxenye ezisetshenziswa ekugcineni.

I-CNC machining copper idinga ukusetshenziswa kwesoftware ekhethekile kanye nemishini ye-CNC efakwe amathuluzi afanele ukusika nokulolonga izinto ngokunembile. Inqubo iqala ngokwakha imodeli ye-3D yengxenye oyifunayo ohlelweni lwe-CAD. Imodeli ye-3D ibe isiguqulwa ibe indlela yamathuluzi, okuyisethi yemiyalelo ehlela umshini we-CNC ukuze ukhiqize umumo oyifunayo.

Umshini we-CNC ube usulayishwa izinto ezisetshenziswayo ezifanele, njengezigayo nezinsimbi zokubhoboza, bese impahla ilayishwa emshinini. I-material ibe seyenziwa ngomshini ngokulandela indlela yamathuluzi ehleliwe bese kukhiqizwa umumo oyifunayo. Ngemuva kokuthi inqubo yomshini isiqediwe, ingxenye iyahlolwa ukuze kuqinisekiswe ukuthi ihlangabezana nemibandela. Uma kunesidingo, ingxenye ibe isiqedwa ngezinqubo ezihlukahlukene zokunyathelisa ngemva komshini njengokubhafa nokupholisha.

Yiziphi izingxenye zemishini ye-CNC ezingasebenzisa i-Copper

Izingxenye zethusi zomshini we-CNC zingasetshenziselwa izinhlelo zokusebenza ezihlukahlukene, okuhlanganisa izingxenye ze-elekthronikhi nezixhumi, izingxenye zezimoto ezinembayo eziphezulu, izingxenye ze-aerospace, imishini yezokwelapha, imihlangano yemishini eyinkimbinkimbi nokunye. Izingxenye zomshini ze-Copper CNC zivame ukugcwaliswa nezinye izinsimbi ukuze kuthuthukiswe ukusebenza kahle noma ukumelana nokugqoka.

Izingxenye zethusi zomshini we-CNC zingasetshenziselwa izinhlelo zokusebenza ezihlukahlukene, okuhlanganisa izixhumi zikagesi, izindlu zezimoto, izishintshisi zokushisa, izingxenye zamandla eziwuketshezi, izingxenye zesakhiwo, nezingxenye zokuhlobisa. Izingxenye zethusi zilungele ukwenziwa kwemishini ye-CNC ngenxa yokuguquguquka kwayo okuphezulu kagesi nokushisayo, kanye nokumelana kwayo nokugqwala okuhle kakhulu. I-CNC machining copper ingasetshenziswa futhi ukudala izimo eziyinkimbinkimbi nezingxenye ezinokubekezelelana okunembile.

Hlobo luni lokwelashwa komhlaba olufanele izingxenye ze-CNC zemishini ye-Copper

Ukwelashwa kwendawo efanele kakhulu yezingxenye zethusi ze-CNC yi-anodizing. I-Anodizing iyinqubo ehlanganisa i-electro ukwelapha insimbi ngamakhemikhali nokwenza ungqimba lwe-oxide ebusweni bento okwandisa ukumelana nokuguga nokuvikela ukugqwala. Ingase futhi isetshenziselwe ukuhlinzeka ngeziqephu zokuhlobisa njengemibala egqamile, isiphetho se-matte noma amathoni akhazimulayo.

Ama-alloys ethusi ngokuvamile aphathwa nge-electroless nickel plating, i-anodizing, kanye ne-passivation ukuvikela indawo engaphezulu ekugqwaleni nasekuguge. Lezi zinqubo nazo zisetshenziselwa ukuthuthukisa ubuhle bengxenye.

Isicelo:

Imboni ye-3C, umhlobiso wokukhanyisa, izinto zikagesi, izingxenye zezimoto, izingxenye zefenisha, ithuluzi likagesi, okokwelashwa, okokusebenza okuzenzakalelayo okuhlakaniphile, ezinye izingxenye zensimbi zokuphonsa.