1. Ukumaka kwe-laser

Ukumaka kwe-laser kuyindlela ejwayelekile yokumaka unomphela izingxenye ze-CNC Machining Doccents ngokunemba okuphezulu nokunemba. Le nqubo ifaka ukusebenzisa i-laser ku-etch umaki unomphela ongaphezulu kwengxenye.

Inqubo yokumaka ama-laser iqala ngokuklama umaki ukuthi ibekwe engxenyeni esebenzisa isoftware ye-CAD. Umshini we-CNC bese usebenzisa lo mklamo ukuqondisa ugongolo lwe-laser endaweni eqondile engxenyeni. Ugongolo lwe-laser bese lushisa ingaphezulu lengxenye, okwenza ukusabela okuholela kuphawu lwaphakade.

Ukumaka kwe-laser kuyinqubo engeyona eyokuxhumana, okusho ukuthi akukho ukuxhumana ngokomzimba phakathi kwe-laser kanye nengxenye. Lokhu kwenza kube lula ukumaka izingxenye ezintekenteke noma ezintekenteke ngaphandle kokudala umonakalo. Ngokwengeziwe, ukumaka kwe-laser kufinyeleleka kakhulu, kuvumela uhla olubanzi lwamafonti, osayizi, kanye nemiklamo okufanele isetshenziselwe uphawu.

Izinzuzo zokumaka kwe-laser ezingxenyeni zemishini ye-CNC zifaka ukucaciswa okuphezulu nokunemba, ukumaka okungapheli, nenqubo engeyona yokuxhumana inciphisa ukulimala kwezingxenye ezibucayi. Isetshenziswa kakhulu kwizimoto zezimoto, ze-aerospace, ezokwelashwa, kanye nezokwelashwa ezilandelwayo ukumaka izingxenye ngezinombolo ze-serial, ama-logo, ama-barcode, namanye amamaki wokuhlonza.

Sekukonke, ukumaka kwe-laser kuyindlela ephumelela kakhulu futhi esebenza kahle yokumaka izingxenye zemishini ye-CNC ngokunemba, ukunemba, nokuhlala njalo.

2. I-CNC eqopha

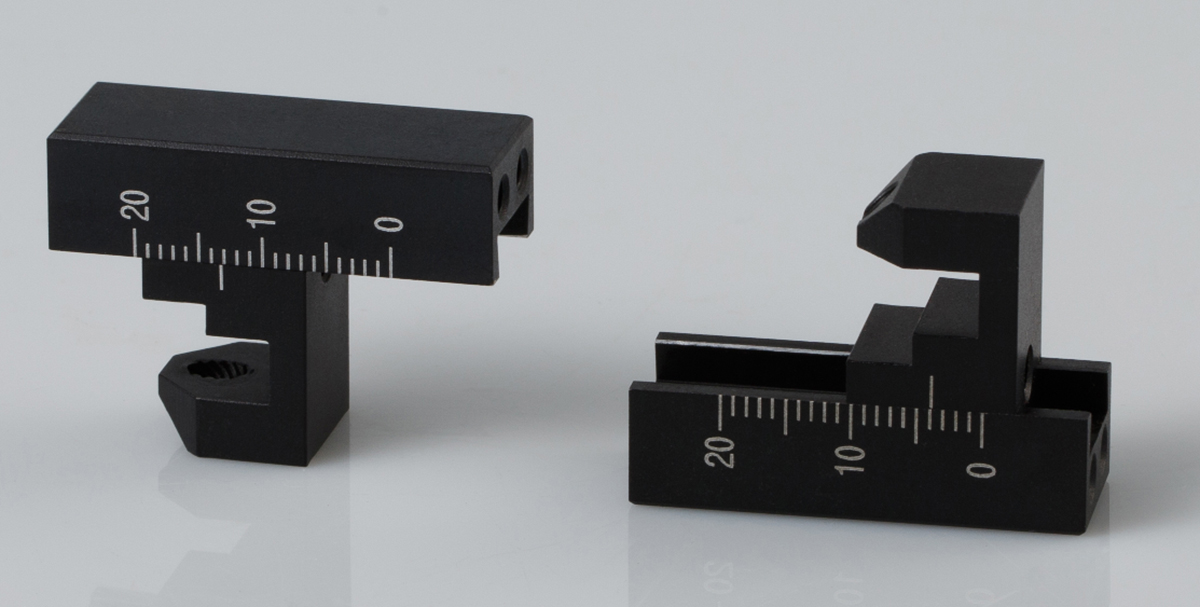

Ukuqopha kuyinqubo evamile esetshenziswa engxenyeni yomshini we-CNC ukudala amamaki aphakade, anembe ephezulu ebusweni bezingxenye. Le nqubo ifaka ukusebenzisa ithuluzi, imvamisa i-Carbide Bit noma ithuluzi ledayimane, ukususa impahla ebusweni bengxenye ukudala okuqoshwa okufisayo.

Ukuqoshwa kungasetshenziswa ukudala amamaki ahlukahlukene ezingxenyeni, kufaka phakathi umbhalo, ama-logo, izinombolo ezi-serial, namaphethini wokuhlobisa. Inqubo ingenziwa ngezinto eziningi zokwakha, kufaka phakathi izinsimbi, amapulasitiki, ubumba, kanye nama-composites.

Inqubo yokuqopha iqala ngokuklama umaki oyifunayo usebenzisa i-CAD Software. Umshini we-CNC bese uhlelwe ukuqondisa ithuluzi endaweni eqondile engxenyeni lapho kuzalwa khona uphawu. Ithuluzi labe selitholwa ebusweni bengxenye futhi lijikeleze ngesivinini esikhulu ngenkathi lisusa izinto zokwakha umaki.

Ukuqoshwa kungenziwa kusetshenziswa amasu ahlukene, kufaka phakathi ukufakwa komugqa, okuqoshwe amachashazi, kanye nokuqoshwa kwe-3D. Ukuqoshwa komugqa kubandakanya ukudala umugqa oqhubekayo ebusweni bakwengxenye, ngenkathi ukufiphala amachashazi kubandakanya ukudala uchungechunge lwamachashazi ahlukaniswe eduze. Ukuqoshwa kwe-3D kubandakanya ukusebenzisa ithuluzi ukususa impahla ngokujula okuhlukile ukudala impumuzo enezici ezintathu ebusweni bakwengxenye.

Izinzuzo zokuqoshwa kwezingxenye zemishini ye-CNC zifaka ukunemba okuphezulu nokunemba, ukumaka okungapheli, kanye nekhono lokwakha amamaki ahlukahlukene ngezinto ezahlukahlukene zezinto ezahlukahlukene. Ukuqoshwa kuvame ukusetshenziswa kwizitamputhu zezimoto, ze-aerospace, zezokwelapha, kanye nezokwelashwa ze-elekthronikhi ukudala amamaki aphakade ezingxenyeni zokuhlonza nezinhloso zokulandela umkhondo.

Sekukonke, okuqoshwe kuyinqubo ephumelelayo nenembile engadala amamaki asezingeni eliphakeme kwizingxenye zamamaini we-CNC.

3. Ukumaka kwe-EDM

I-EDM (Ukukhishwa Kwemishini Kagesi) Ukumaka kuyinqubo esetshenziselwa ukudala amamaki aphakade kwizakhi zemishini ye-CNC. Le nqubo ifaka ukusebenzisa umshini we-EDM ukudala ukukhipha okulawulwa kwe-spark phakathi kwe-electrode kanye nengxenye yengxenye, esusa umaki oyifunayo.

Inqubo yokumaka i-EDM iqondile kakhulu futhi ingadala amamaki amahle kakhulu, anemininingwane ebusweni bezakhi. Ingasetshenziswa ezinhlolweni eziningi zezinto zokwakha, kufaka phakathi izinsimbi ezifana nensimbi, insimbi engagqwali, ne-aluminium, kanye nezinye izinto ezinjenge-ceramics ne-graphite.

Inqubo yokumaka i-EDM iqala ngokuklama umaki oyifunayo usebenzisa i-CAD Software. Umshini we-EDM bese uhlelwe ukuqondisa i-electrode endaweni eqondile engxenyeni lapho kuzalwa khona uphawu. I-electrode iyehliswa ebusweni bengxenye, futhi ukukhishwa kukagesi kudalwe phakathi kwe-electrode nengxenye, okususa impahla nokwakha umaki.

Ukumaka kwe-EDM kunezinzuzo eziningana kwimishini ye-CNC, kufaka phakathi amamaki ayo okudala amamaki anemininingwane eqondile, amandla awo okumaka izinto ezinzima noma ezinzima ukudala amamaki ezindaweni ezivundisiwe noma ezingekho emthethweni. Ngaphezu kwalokho, inqubo ayibandakanyi ukuxhumana ngokomzimba nengxenye, enciphisa ubungozi bomonakalo.

Ukumaka kwe-EDM kuvame ukusetshenziswa e-Aerospace, izimoto ezinezimoto, nezimboni zezokwelapha ukumaka izingxenye ngezinombolo zokuhlonza, izinombolo ze-serial, nolunye ulwazi. Sekukonke, ukumaka i-EDM kuyindlela ephumelelayo nenembile yokwakha amamaki aphakade kwizakhi zemishini ye-CNC.