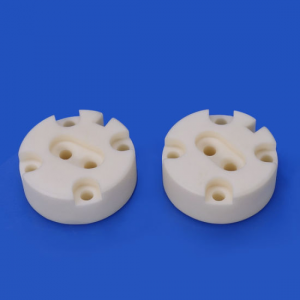

Izingxenye ze-Ceramics CNC Ukucacisa izingxenye zemishini

Ukucaciswa kwe-CNC Machching Ceramics

I-CNC MachingAning of Curamics inqubo yokusika nokubumba izinto zokwakha ubumba usebenzisa imishini yokulawula izinombolo (CNC). Kuyinqubo eqondile futhi enembile kakhulu engasetshenziswa ukukhiqiza izingxenye ngokubekezelelana okuqinile nezinkwa eziyinkimbinkimbi. Imishini ye-CNC yama-ceramics ingahle isetshenziselwe ukudala izakhi zemboni ehlukahlukene, kufaka phakathi i-aerospace, ezokwelapha nezenzeli.

Inqubo ye-CNC Maching iqala ngokukhethwa kwezinto ezifanele zobumba ze-ceramic zohlelo oluhlosiwe. Ngokuya ngohlelo, izinto ze-ceramic zingasukela ku-alumina, zirconia, kanye ne-silicon nitride ku-aluminium oxide kanye ne-silicon carbide. Lapho nje kukhethwe lokho okukhethiwe, ukwakheka okufunayo kuhlelwe emshinini we-CNC. Umshini we-CNC bese usika ngqo impahla ye-ceramic esimweni esifunekayo.

Lapho impahla ye-ceramic isikiwe, yabe isipolikezi uma kunesidingo. Kwezakhi ezidinga ukuqedwa okubushelelezi, iDayimane Abrasive isetshenziswa ngokujwayelekile. Le nqubo nayo isetshenziselwa ukukhiqiza imininingwane eyinkimbinkimbi nobunjwa obuyinkimbinkimbi. Ngemuva kokuba izinto zobumba ze-ceramic zipolishwe, bese zihlolelwa ukuqinisekiswa kwekhwalithi. Ekugcineni, izakhi zibe sezingeniswa ezinye izindlela zokwelapha ezifana nokwelashwa okushisa, ukwelashwa okungaphezulu, kanye nezambatho.

Sigxila ekwenziweni kokunemba okungekho emthethweni kwe-aluminium izingxenye zezinhlaka eziyinkimbinkimbi futhi zizibophezele ekuletheni ukunemba okuphezulu kanye nezinto ezingaguquki kumakhasimende ethu. Siyaqhubeka nokutshala imali emishini yomshini ye-CNC entsha kanye nabasebenzi abanamakhono ukuqinisekisa ukuthi iqembu lethu ligcina inzuzo eqinile yokuncintisana. Siphinde sathuthukisa inqubo ye-aluminium machishini ukuthuthukisa ukusebenza kahle nekhwalithi, futhi siqhubeke nokuhlangabezana nezidingo zokukhiqiza amakhasimende.

Inzuzo ye-CNC Machching Ceramics

1. Ukucaciswa okuphezulu: I-CNC Maching Maching Curamics ingafinyelela ukunemba okuphezulu kwemishini nokuphindaphindwa, okungahlangabezana nezidingo zezingxenye eziyinkimbinkimbi mabhuku kanye nemishini eyinkimbinkimbi yemishini.

2. Ukusebenza okuphezulu: ngosizo lwe-CNC Maching Maching, isikhathi sokucubungula izingxenye eziyinkimbinkimbi ze-ceramic sifinyezwa kakhulu, futhi ukusebenza kahle kokukhiqiza kuyathuthuka.

I-3. Izindleko eziphansi: I-CNC Maching Curamics inganciphisa kakhulu izindleko zokucutshungulwa kwezingxenye zobumba, futhi ibe nezinzuzo ezinhle zezomnotho.

I-4. Ukwethenjwa okuphezulu: I-CNC Machching Ceramics ingaqinisekisa ukunemba kwemishini yezingxenye zobumba futhi kuqinisekiswe ukuvumelana kwezingxenye.

Ikhwalithi ephezulu ye-CNC Imashini ye-CNC ingathuthukisa ukuqedwa komhlaba kwezingxenye ze-ceramic, futhi yenza izingxenye zobumba zibushelelezi futhi zihle.

Izande kangakanani izingxenye zemishini ye-CNC

I-CNC Mailching of Curamics inqubo eqondile edinga amathuluzi akhethekile nemishini. Okokuqala, ifayela le-CAD lenziwa noma ifayela le-CAD elikhona liguqulwa ukuchaza ingxenye yeJiyomethri. Ifayela le-CAD lingeniswa kwisilawuli somshini we-CNC, lapho isetshenziselwa ukukhiqiza indlela yamathuluzi. Umshini we-CNC bese uswakama ngamathuluzi afanele wokusika, anjenge-End Mills End Diamond-Tiped End kanye ne-Carbide Drill, futhi ingxenye ilayishwe emshinini. Ekugcineni, umshini we-CNC usebenza ukusika ingxenye ngokuya ngendlela ekhiqizwayo yamathuluzi. Imishini ye-CNC yama-ceramics imvamisa isetshenziselwa ukudala ama-geometries ayinkimbinkimbi, njengokufakwa kwezokwelapha, izakhi ze-elekthronikhi, kanye nama-turbine blade.

Yiziphi izingxenye zemishini ye-CNC ezingasebenzi ngo-ceramics

Izingxenye zemishini ye-CNC zama-ceramics zivame ukufaka ama-cutters, amamitha ama-end, ama-drill, ama-router, amasaha, nama-grinders. Amanye amathuluzi asetshenziselwa umshini we-CNC wama-ceramics afaka ama-cuter arrasive, ama-diamond cutters, kanye ne-diamond dengwane. Lawa mathuluzi asetshenziselwa ukudala ukwakheka okuyinkimbinkimbi futhi afeze ukuqeda okuqondile ezinhlobonhlobo zezakhi ze-ceramic.

Hlobo luni lokwelashwa komhlaba olufanele izingxenye zemishini ye-CNC yama-ceramics

Izindlela zokwelashwa ezivame kakhulu ze-CNC imishini ye-ceramics zipholisha, iSandbsting, futhi i-anodizing. Ngokuya ngohlelo lokusebenza, ezinye izindlela zokwelapha ezinjengokuqokwa, ukupenda, kanye ne-powder coating nazo zingasetshenziswa.

Izingxenye zemishini ye-CNC ezingasetjenziswa ama-ceramics we-CNC Maching Curamics zifaka ama-End Mills, ama-routers, ama-drill, ama-chamfer mill kanye nama-drill bits.