Yini i-die casting

I-Die casting inqubo yokukhiqiza esetshenziselwa ukukhiqiza izingxenye zensimbi ezinokunemba okuphezulu nokuqedwa kwendawo. Kuhilela ukuphoqelela insimbi encibilikisiwe endaweni yokubumba ngaphansi kwengcindezi ephezulu. Isikhunta sesikhunta sidalwa yizinsimbi ezimbili eziqinile ezifayo ezifakwe ngomshini zibe yisimo esifunwayo.

Inqubo iqala ngokuncibilika kwensimbi, ngokuvamile i-aluminium, i-zinc, noma i-magnesium, esithandweni. Insimbi encibilikisiwe ibe isijova esibunjeni ngomfutho omkhulu kusetshenziswa umshini wokunyathelisa we-hydraulic. Insimbi iqina ngokushesha ngaphakathi kwesikhunta, futhi izingxenye ezimbili zesikhunta ziyavuleka ukuze kukhululwe ingxenye eqediwe.

I-Die casting isetshenziswa kabanzi ukukhiqiza izingxenye ezinobunjwa obuyinkimbinkimbi nezindonga ezincane, njengamabhulokhi enjini, izindlu zokudlulisela, kanye nezingxenye zezimoto kanye ne-aerospace ehlukahlukene. Le nqubo iphinde idume ekukhiqizeni izimpahla ezithengwayo, njengamathoyizi, i-kitchenware, nezinto zikagesi.

I-Pressure Die Casting

I-Die casting iyinqubo ekhethekile eye yathuthukiswa kakhulu phakathi nekhulu lama-20. Inqubo eyisisekelo ihlanganisa: Insimbi encibilikisiwe ithululelwa/ijovwe esikhunjeni sensimbi futhi ngesivinini esiphezulu, ingcindezi engaguquki kanye neqinisayo (ekugayweni komfutho wegazi) kanye nokupholisa insimbi encibilikisiwe iqina ukuze yakhe ukubunjwa okuqinile. Ngokuvamile, inqubo ngokwayo ithatha imizuzwana embalwa futhi iyindlela esheshayo yokwenza umkhiqizo wensimbi ovela ezintweni ezingavuthiwe. I-die casting ifanele izinto ezifana ne-tin, lead, zinc, i-aluminium, i-magnesium kuya kuma-alloys ethusi ngisho nama-alloys ensimbi njengensimbi engagqwali. Ama-alloys amakhulu asetshenziswa namuhla ekukhiqizeni i-pressure die cast yi-aluminium, zinc ne-magnesium. Kusukela emishinini yokuqala ye-die cast eqondise amathuluzi e-die ekuqondeni mpo kuya ezingeni elivamile manje lokuma okuvundlile nokusebenza, ukuqinisa amabha othayi amane kanye nezigaba zenqubo elawulwa ngokugcwele yikhompyutha inqubo eye yathuthuka kuyo yonke iminyaka.

Imboni isikhule yaba umshini wokukhiqiza emhlabeni wonke, yenza izingxenye zezinhlelo zokusebenza ezihlukahlukene, eziningi zazo ezizokwazi ukufinyeleleka kuzo njengoba ukusetshenziswa komkhiqizo we-die castings kuhluke kakhulu.

Izinzuzo zokucindezela ziyafa

Ezinye zezinzuzo ze-high pressure die cast:

• Inqubo ifanele ukukhiqizwa kwevolumu ephezulu.

• Khiqiza ukulingwa okuyinkimbinkimbi ngokushesha uma kuqhathaniswa nezinye izinqubo zokwenza insimbi (isb. ukukhanda).

• Izingxenye zamandla aphezulu ezikhiqizwe esimweni sokulinywa (kuncike ekwakhiweni kwengxenye).

• Ukuphindaphinda kobukhulu.

• Izingxenye zodonga ezizacile zingenzeka (isb. 1-2.5mm).

• Ukubekezelelana okuhle komugqa (isb. 2mm/m).

• Ukuqedwa kahle kwendawo (isb. 0.5-3 µm).

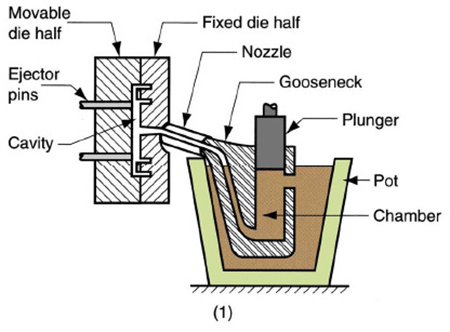

Ngenxa yalolu hlelo “oluvaliwe” lwensimbi oluncibilikayo/lomjovo kanye nokunyakaza okuncane komshini oshisayo we-hot chamber kunganikeza umnotho ongcono wokukhiqiza. Ingxubevange yensimbi ye-Zinc isetshenziswa ngokuyinhloko ku-hot room pressure die casting enephuzu elincibilikayo eliphansi elinikeza izinzuzo ezengeziwe zokuguga okuphansi emishinini (ibhodwe, i-gooseneck, umkhono, i-plunger, umlomo wombhobho) kanye nokuguga okuphansi kumathuluzi okufa (impilo ende yamathuluzi uma iqhathaniswa namathuluzi okusakaza e-aluminium - kuncike ekwamukelweni kwekhwalithi yokuphonsa).

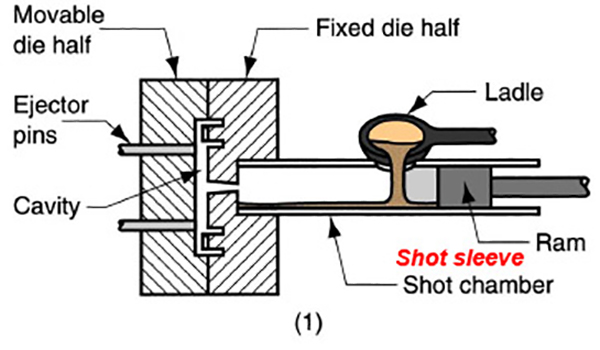

Imishini yasekamelweni elibandayo ifanele ukuphonswa kwe-aluminium, izingxenye emshinini (umkhono wokudubula, ithiphu le-plunger) zingashintshwa ngokuhamba kwesikhathi, imikhono ingaphathwa ngensimbi ukuze kwandiswe ukuqina kwayo. Ingxubevange ye-aluminiyamu incibilika ku-ceramic crucible ngenxa yezinga eliphezulu lokuncibilika le-aluminium kanye nesidingo sokunciphisa ingcuphe yokulandwa kwensimbi okuyingozi ngaphakathi kwezinsimbi ezisansimbi. Ngenxa yokuthi i-aluminiyamu iyingxube yensimbi elula uma kuqhathaniswa, ivumela ukulingwa kwezinhlayiya ezinkulu nezisindayo noma lapho kudingeka khona amandla angeziwe kanye nokukhanya ekubunjweni kwe-die.