Kuyini ukuganga?

I-Forging isho inqubo yokubumba insimbi (noma ezinye izinto) ngokuyishisisa izinga lokushisa eliphezulu bese uyishaya ngesando noma uyicindezele ukuze ingene esimweni oyifunayo. Inqubo yokufoja ivamise ukusetshenziselwa ukwakha izinto eziqinile nezihlala isikhathi eside, njengamathuluzi, izikhali, nezingxenye zomshini. Insimbi iyashiswa ize ithambile futhi ithambile, bese ibekwa phezu kwe-anvil futhi ibunjwe kusetshenziswa isando noma ukucindezela.

Forging Izinhlobo

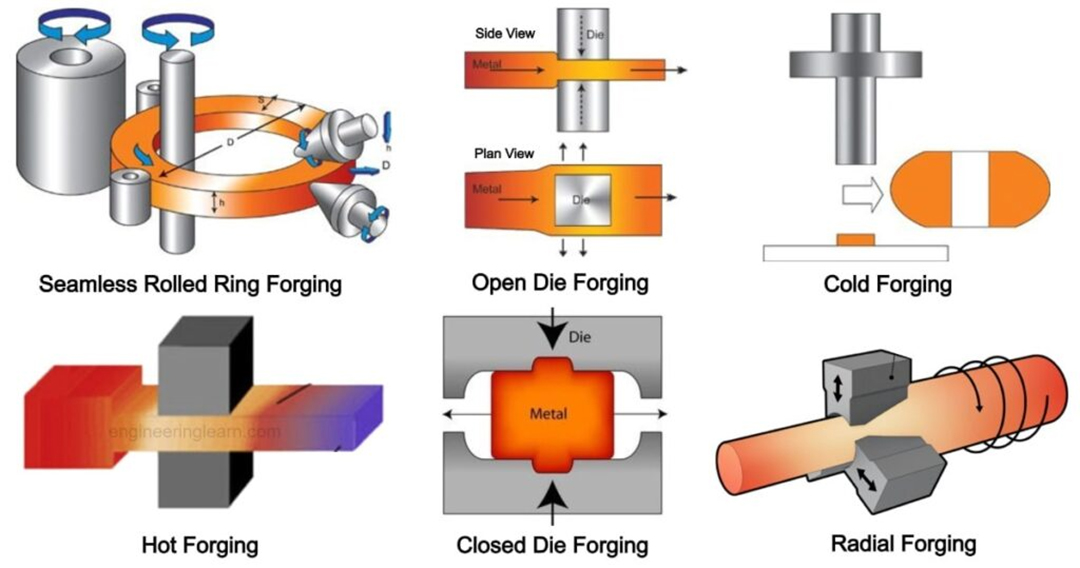

I-Forging inqubo yokwenza insimbi lapho impahla yensimbi ishiselwa esimweni sepulasitiki futhi isetshenziswe ngamandla ukuyikhubaza ibe yisimo esidingekayo. Ngokwezindlela ezihlukene zokuhlukanisa, ukubumba kungahlukaniswa ngezinhlobo ezahlukene, okulandelayo kunezindlela ezijwayelekile zokuhlukanisa:

- Ngokwesimo sensimbi ngesikhathi sokubumba, ukubumba kungahlukaniswa ngezinhlobo ezilandelayo:

Cold Forging: Cold Forging iyindlela yokusebenza yensimbi yokucubungula isitokwe sebha bese uyikhama endaweni evulekile. Le ndlela kwenzeka lokushisa atambient noma ngaphansi lokushisa recrystallization metal sika ukwakha insimbi ibe ijamo oyifunayo.

I-Hot Forging: Ukushisa izinto zensimbi ezingeni elithile lokushisa ukuze zizenze zibe yipulasitiki eyengeziwe, bese zenza i-hammering, i-extrusion nokunye ukucutshungulwa.

Ukubumba okufudumele: Phakathi kokubumba okubandayo nokushisa okushisayo, izinto zensimbi zishiswa ekushiseni okuphansi ukuze kube lula ukwenziwa ipulasitiki, bese kwenziwa i-hammered, extruded nezinye izinqubo.

- Ngokuya ngezinqubo ezahlukene zokubumba, ukubumba kungahlukaniswa ngezinhlobo ezilandelayo:

Ukufoja kwamahhala: okwaziwa nangokuthi ukufoja kwesando samahhala, kuyindlela yokusando nokukhipha insimbi ngokuwa kwamahhala kwekhanda lesando emshinini wokubumba.

I-Die forging: Indlela yokwenza insimbi ngokuyicindezela kwidayidi usebenzisa idiyizi yensimbi ethile.

I-Precision forging: indlela yokubumba yokukhiqiza izingxenye ezinembayo nezimfuneko zekhwalithi ephezulu.

Ukwakhiwa kwePlastiki: Kuhlanganisa ukugingqa, ukwelula, ukunyathela, ukudweba okujulile nezinye izindlela zokwakha, kubuye kubhekwe njengendlela yokubumba.

- Ngokuya ngezinto zokwakha ezahlukahlukene, ukubumba kungahlukaniswa ngezinhlobo ezilandelayo:

I-Brass Forging: ibhekisela ezinqubweni ezihlukahlukene zokubumba zethusi nama-alloys ayo.

I-aluminium alloy forging: ibhekisela ezinqubweni ezihlukahlukene zokubumba ze-aluminium nama-alloys ayo.

I-Titanium alloy forging: ibhekisela ezinqubweni ezihlukahlukene zokubumba ze-titanium nama-alloys ayo.

Ukubumba insimbi engagqwali: kubhekisela ezinqubweni ezihlukahlukene zokubumba zensimbi engagqwali nama-alloys ayo.

- Ngokuya ngezimo ezihlukene zokubumba, ukubumba kungahlukaniswa ngezinhlobo ezilandelayo:

I-flat forging: ukucindezela izinto zensimbi zibe yisimo esiyisicaba ngokuya ngokujiya nobubanzi obuthile.

I-Cone Forging: Ukucindezela into yensimbi ibe yisimo esiyikhonikhi.

Ukugobela ukubumba: ukwenza insimbi ibe yisimo esifiswayo ngokugoba.

Ukubumba indandatho: Ukubumba insimbi ibe yisimo esiyindandatho.

- Ngokuya ngengcindezi yokubumba ehlukene, ukubumba kungahlukaniswa ngezinhlobo ezilandelayo:

Ukugxiviza: Ukusebenza kwensimbi ngaphansi kwengcindezi ephansi, ngokuvamile kulungele ukukhiqizwa kwezingxenye zensimbi ezizacile.

I-Medium-pressure forging: Idinga ingcindezi enkulu kunokugxiviza futhi ngokuvamile ifaneleka ukukhiqiza izingxenye zogqinsi olumaphakathi.

I-High Pressure Forging: I-Forging idinga ingcindezi enkulu futhi ngokuvamile ifaneleka ukukhiqiza izingxenye eziwugqinsi.

- Ngokuya ngezinhlelo zokusebenza zokukhohlisa ezahlukahlukene, ukuqamba kungahlukaniswa ngezinhlobo ezilandelayo:

Izingxenye ze-Auto Forging: Yakha izingxenye ezihlukahlukene ezidinga ukusetshenziswa ezimotweni, njengezingxenye zenjini, izingxenye ze-chassis, njll.

I-Aerospace forging: izingxenye ezidingekayo ekwenzeni izindiza, amarokhethi kanye nezinye izinto zasemkhathini.

I-Energy Forging: Khiqiza izingxenye ezidingekayo kumishini yamandla ehlukahlukene, njengama-boilers, izinjini zegesi, njll.

Ukufoja ngomshini: Yenza izingxenye ezidinga ukusetshenziswa emishinini eyahlukene, njengama-bearing, amagiya, izinduku zokuxhuma, njll.

1. Amandla athuthukisiwe nokuqina:I-Forging ingathuthukisa izakhiwo zemishini yensimbi, iyenze ibe namandla futhi ihlale isikhathi eside.

2. Ukubumba ngokunemba:Ukubumba kuvumela ukubumba okunembayo kwensimbi, okubalulekile ekukhiqizeni izingxenye ezinomumo nosayizi othize.

3. Izinto ezibonakalayo ezithuthukisiwe:Inqubo yokubumba ingathuthukisa izakhiwo zensimbi, njengokumelana nokugqwala nokumelana nokugqokwa, ikwenze ifaneleke kakhulu izicelo ezifunayo.

4. Imfucuza eyehlisiwe:Uma kuqhathaniswa nezinye izinqubo zensimbi, ukubumba kukhiqiza imfucuza encane futhi kuvumela ukusetshenziswa okungcono kwempahla, okungasiza ekunciphiseni izindleko.

5. Isiphetho sendawo esithuthukisiwe:Ukuqamba kungaholela ekuqedeni okubushelelezi, okubalulekile ezingxenyeni ezidinga ukuhlangana ndawonye noma zishelele zibhekane.

6. Ukwandisa ukusebenza kahle kokukhiqiza:Ngokuthuthuka kwezobuchwepheshe bokuqamba, inqubo isiye yashesha futhi isebenza kahle, okuvumela ukwanda komkhiqizo.