Hlobo luni lwezinto ezikhethekile ezizosetshenziswa ezingxenyeni zomshini zikawoyela neGesi CNC?

Izingxenye zomshini we-CNC ezisetshenziswa embonini kawoyela negesi zidinga izinto ezikhethekile ezingamelana nengcindezi ephezulu, izinga lokushisa eliphezulu, kanye nezindawo ezibolayo. Nazi ezinye zezinto ezikhethekile ezivame ukusetshenziswa ezingxenyeni zikawoyela negesi ze-CNC kanye namakhodi azo wezinto ezibonakalayo:

Lapho ukhetha i-material yezingxenye zomshini kawoyela negesi ye-CNC, kubalulekile ukucabangela izidingo ezithile zohlelo lokusebenza, njengokucindezela, izinga lokushisa, nokumelana nokugqwala. Izinto ezibonakalayo kufanele zikhethwe ngokucophelela ukuze kuqinisekiswe ukuthi ingxenye ingakwazi ukumelana nemithwalo elindelekile nezimo zemvelo futhi inikeze ukusebenza okuthembekile phezu kwempilo yesevisi ehlosiwe.

| I-Oil Normal Material | Ikhodi ye-Oil Material |

| I-Nickel Alloy | IMINYAKA engu-925,INCONEL 718(120,125,150,160 KSI),NITRONIC 50HS,MONEL K500 |

| Insimbi engagqwali | 9CR,13CR,SUPER 13CR,410SSTANN,15-5PH H1025,17-4PH(H900/H1025/H1075/H1150) |

| I-Non-magnetic Stainless Steel | 15-15LC,P530,Idatha yedatha 2 |

| I-alloy Steel | S-7,8620,SAE 5210,4140,4145H MOD,4330V,4340 |

| Ingxubevange yethusi | AMPC 45,TOUGHMET,BRASS C36000,BRASS C26000,BeCu C17200,C17300 |

| I-Titanium Alloy | I-CP TITANIUM GR.4,Ti-6AI-4V, |

| I-Cobalt-base Alloys | I-STELLITE 6,MP35N |

Hlobo luni lwezinto ezikhethekile ezizosetshenziswa ezingxenyeni zomshini zikawoyela neGesi CNC?

Imicu ekhethekile esetshenziswa ezingxenyeni zomshini kawoyela negesi ye-CNC kumele yakhelwe ukuhlangabezana nezidingo ezithile zohlelo lokusebenza, njengokucindezela okukhulu, izinga lokushisa eliphezulu, nezimo zemvelo ezinzima. Izintambo ezisetshenziswa kakhulu embonini kawoyela negesi zihlanganisa:

Yenza kabusha impendulo

Lapho ukhetha intambo kawoyela negesi izingxenye zomshini we-CNC, kubalulekile ukucabangela izidingo ezithile zohlelo bese ukhetha intambo engakwazi ukumelana nemithwalo elindelekile nezimo zemvelo. Kubalulekile futhi ukuqinisekisa ukuthi intambo ikhiqizwa kumazinga afanele kanye nemininingwane ukuze kuqinisekiswe ukuhambisana nezinye izingxenye ohlelweni.

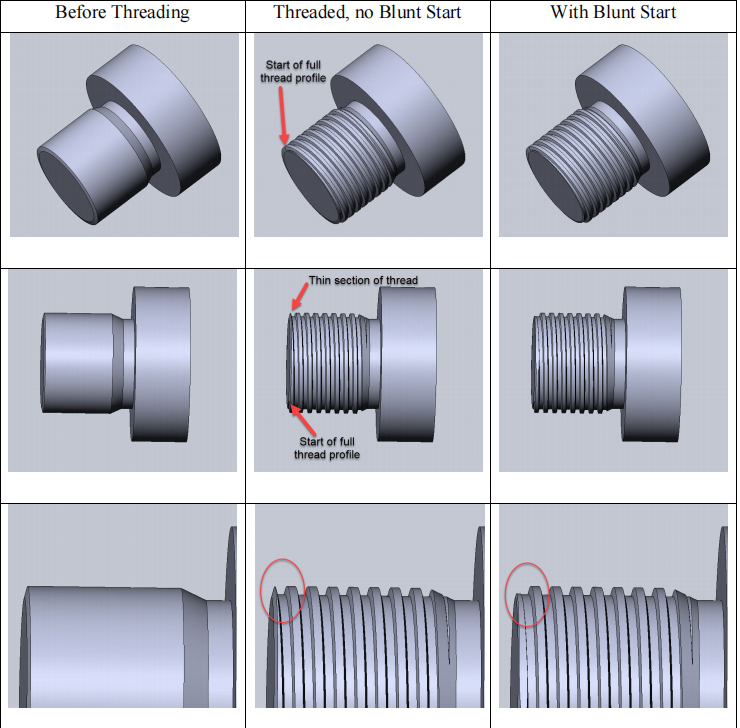

Nalu uchungechunge olukhethekile lwereferensi:

| Uhlobo Lwentambo Yamafutha | Ukwelashwa Okukhethekile Kwamafutha |

| Uchungechunge lwe-UNRC | Vacuum electron beam welding |

| Uchungechunge lwe-UNRF | Flame sprayed (HOVF) nickel tungsten carbide |

| TC Uchungechunge | I-Copper Plating |

| Uchungechunge lwe-API | I-HVAF (High Velocity Air Fuel) |

| Intambo ye-Spiralock | I-HVOF (High Velocity Oxy-Fuel) |

| Uchungechunge Oluyisikwele |

|

| Intambo ye-Buttress |

|

| Uchungechunge Olukhethekile Lwe-Buttress |

|

| Uchungechunge lwe-OTIS SLB |

|

| Uchungechunge lwe-NPT |

|

| Rp(PS)Uchungechunge |

|

| RC(PT)Uchungechunge |

Hlobo luni lokwelapha okukhethekile okuzosetshenziswa ezingxenyeni zomshini ze-CNC zikawoyela neGesi?

Ukwelashwa okungaphezulu kwezingxenye zomshini we-CNC kuyisici esibalulekile sokuqinisekisa ukusebenza kwazo, ukuqina, nokuphila isikhathi eside ezimeni ezinzima zomkhakha kawoyela negesi. Kunezinhlobo eziningana zokwelapha zangaphandle ezivame ukusetshenziswa kulo mkhakha, okuhlanganisa:

Kubalulekile ukukhetha ukwelashwa kwendawo efanele ngokusekelwe ekusetshenzisweni okuqondile kanye nezimo zokusebenza zezingxenye zomshini we-CNC embonini kawoyela negesi. Lokhu kuzoqinisekisa ukuthi izingxenye ziyakwazi ukumelana nezimo ezinzima futhi zenze umsebenzi wazo ohlosiwe ngempumelelo nangempumelelo.

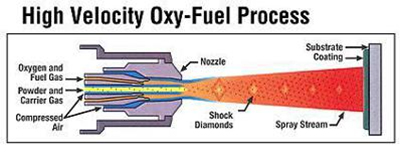

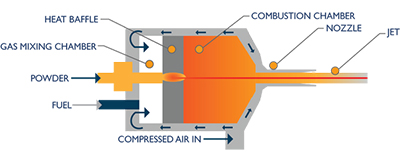

I-HVAF (High-Velocity Air Fuel) &HVOF (High-Velocity Oxygen Fuel)

I-HVAF (I-High-Velocity Air Fuel) kanye ne-HVOF (I-High-Velocity Oxygen Fuel) ubuchwepheshe obubili obuphambili bokunamathela obusetshenziswa kakhulu embonini kawoyela negesi. Lezi zindlela zokwenza izinto zibandakanya ukushisisa into eyimpuphu futhi isheshise ifike ngesivinini esiphezulu ngaphambi kokuyibeka phezu kwengxenye eyenziwe ngomshini. Isivinini esiphezulu sezinhlayiya zempushana siholela ekuhlanganisweni okuminyene futhi okuqinile okunikeza ukumelana okuphakeme kokuguga, ukuguguleka, nokugqwala.

I-HVOF

HVAF

Izembatho ze-HVAF ne-HVOF zingasetshenziswa ukuthuthukisa ukusebenza nempilo yezingxenye zomshini we-CNC embonini kawoyela negesi. Ezinye zezinzuzo zokumbozwa kwe-HVAF ne-HVOF zifaka:

1.Ukumelana Nokugqwala: Izembatho ze-HVAF ne-HVOF zinganikeza ukumelana nokugqwala okuhle kakhulu ezingxenyeni zomshini ezisetshenziswa ezindaweni ezinonya embonini kawoyela negesi. Lezi zembatho zingavikela ingaphezulu lezingxenye ekuchayekeni kumakhemikhali agqwalayo, izinga lokushisa eliphezulu, nezingcindezi eziphezulu.

2.I-Wear Resistance: Izembatho ze-HVAF ne-HVOF zinganikeza ukumelana nokugqokwa okuphezulu ezingxenyeni zomshini ezisetshenziswa embonini kawoyela negesi. Lezi zembatho zingavikela ingaphezulu lezingxenye ekugugeni ngenxa yokuhuzuka, umthelela, nokuguguleka.

3.I-Lubricity Ethuthukisiwe: I-HVAF ne-HVOF yokumbozwa ingathuthukisa ukuthambisa kwezingxenye zomshini ezisetshenziswa embonini kawoyela negesi. Lezi zembatho zinganciphisa ukungqubuzana phakathi kwezingxenye ezihambayo, ezingaholela ekusebenzeni okuthuthukisiwe nokunciphisa ukuguga.

4.Ukumelana Nokushisa: Izembatho ze-HVAF ne-HVOF zinganikeza ukumelana okuhle kakhulu kokushisa ezingxenyeni zomshini ezisetshenziswa embonini kawoyela negesi. Lezi zembatho zingavikela izingxenye ekushayweni okushisayo kanye nokuhamba ngebhayisikili okushisayo, okungaholela ekuqhekekeni nasekuhlulekeni.

5.Kafushane, i-HVAF ne-HVOF inamathela ubuchwepheshe obusezingeni eliphezulu obunganikeza ukuvikeleka okuphezulu ezingxenyeni zomshini ze-CNC ezisetshenziswa embonini kawoyela negesi. Lezi zembozo zingathuthukisa ukusebenza, ukuqina, nempilo yezingxenye, okuholela ekusebenzeni okuthuthukisiwe kanye nokunciphisa izindleko zokulungisa.