Esimeni esiguqukayo sokukhiqiza, ukuthuthuka kwakamuva kuUkunemba kwe-CNC kwenziwa ngomshiniizingxenye ziwukubumba kabusha amabhentshimakhi emboni, ukusetha izindinganiso ezintsha zezingxenye ezenziwe ngokwezifiso kanye nekhono lesitolo semishini yangokwezifiso yesimanje.Lokhu kuguquguquka kwepharadigm akukona nje ukuziphendukela kwemvelo kodwa ukuguquguquka, okuletha inkathi entsha yobunjiniyela obunembayo kanye nokwenza kahle kokukhiqiza.

I-Cutting-Edge Technological Integration

Umnyombo wale ntuthuko ukuhlanganiswa okungenamthungo kobuchwepheshe obusezingeni eliphezulu ngaphakathi kweCNC ukunemba machiningindawo.Izimiso ze-Industrial 4.0, ukukhiqizwa okuhlakaniphile, nokuhlaziywa kwedatha yesikhathi sangempela kuyahlangana ukuze kuthuthukiswe ukukhiqizwa kokuyinkimbinkimbiizingxenye ezenziwe ngomshini.Lokhu kufaka phakathi ukwenziwa kwezingxenye zomshini ze-CNC okugxilwe kuzo ezinhlobonhlobo ezifunwa izimboni ezahlukahlukene.

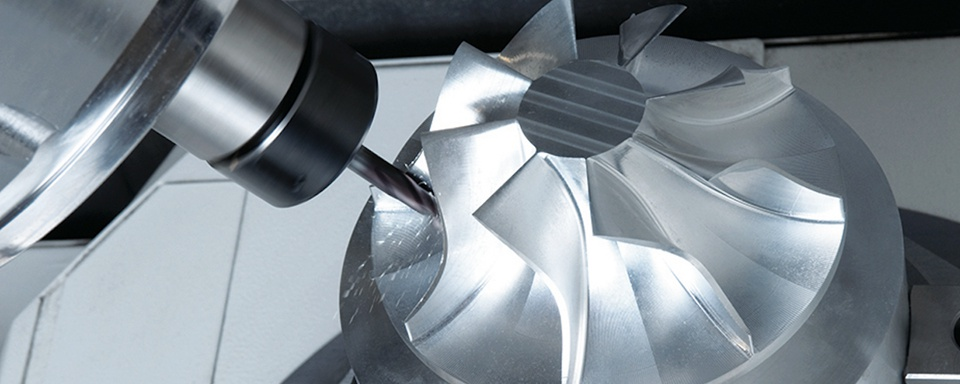

Amasu amasha ku-Multi-Axis Machining

Isici esibalulekile salolu shintsho ukwamukelwa okusabalele kwamasu emishini ye-multi-axis, ebhekelela izidingo zezingxenye ezenziwe ngokwezifiso.Ukunyakaza ngesikhathi esisodwa kuzo zonke izimbazo eziningi akuniki nje amandla ekudalweni kwejiyometri eyinkimbinkimbi kodwa futhi kusiza ukukhiqizwa kwezingxenye ezenziwe ngezifiso ukuze zibe nokucaciswa okunembile.Lokhu kubaluleke kakhulu endaweni ye-izingxenye zensimbi yokukhiqizafuthialuminium CNC machining.

I-Materials Mastery: Ama-alloys angavamile nama-Composites

Intuthuko idlulela ngale kwezinto ezisetshenziswayo zendabuko, inqoba izinselele ezilethwa ama-alloys angavamile nezinhlanganisela ezithuthukisiwe ezingxenyeni zomshini wangokwezifiso.Amathuluzi akhethekile namasu okusika eza phambili, aqinisekisa ukunemba kwemishini yohlu oluhlukahlukene lwezinto.Lokhu kubonakala ikakhulukazi ezinqubweni eziguquguqukayo zokukhiqizwa kwezingxenye ze-CNC.

I-Digital Twin Technology: I-Virtual Prototyping ye-Precision

Ukufakwa kobuchwepheshe bamawele edijithali kuguqule isigaba sokulinganisa, okuyinzuzo ezitolo zemishini yangokwezifiso.Ukulingisa okubonakalayo kuvumela ukulungiselelwa kwamapharamitha womshini, izindlela zamathuluzi, namasu okususa izinto ngaphambi kokuba kuqale ukukhiqizwa komzimba.Lokhu akunciphisi udoti kuphela kodwa futhi kuqinisekisa ukuthi izingxenye zomshini we-CNC zihlangabezana nezindinganiso zekhwalithi eziqinile kakhulu.

Ukubekezelelana Okuqinile kanye Nobuhle beMicromachining

Ukuthuthuka kwemishini yokunemba ye-CNC kuqhubekisele phambili imboni ekubekezeleleni okuqinile kanye nokwenza kahle kwe-micromachining, isici esibalulekile ekukhiqizweni kwezingxenye ezenziwe ngokwezifiso.I-Miniaturization, evame ukubonakala kumishini yezokwelapha kanye ne-electronics, manje isifinyelelwa ngokunemba okungakaze kubonwe ngaphambili, kuchaza kabusha lokho okungafinyelelekaI-CNC iphendule izingxenyeukukhiqiza.

Ukuqinisekiswa Kwekhwalithi Ngokugadwa Kwenqubo Engaphakathi

Ukuze kuhambisane nalokhu kugxuma kwezobuchwepheshe, amasistimu okuqapha angaphakathi kwenqubo aseyingxenye ebalulekile, ikakhulukazi esimweni sesitolo semishini esingokwezifiso.Impendulo yesikhathi sangempela mayelana nesimo samathuluzi, ukunemba kobukhulu, nokuqedwa kwendawo kuvumela ukulungiswa ngokushesha, ukuqinisekisa ukuthi ingxenye ngayinye emshinini, kungakhathaliseki ukuthi izingxenye zomshini we-CNC noma izingxenye eziguqulwe ngokwezifiso, ihlangabezana nezindinganiso eziqondile ezifunwa izimboni zesimanje.

Empeleni, lezi ntuthuko kuUkunemba kwe-CNC kwenziwa ngomshiniizingxenye zeqa imingcele evamile yokukhiqiza, zibeka ibhentshimakhi entsha yezingxenye ezenziwe ngomshini ngokwezifiso kanye nekhono lesitolo semishini yangokwezifiso yesimanje.Njengoba simi esicongweni salesi sikhathi soguquko, kuyabonakala ukuthi ukuphambana kwezobuchwepheshe nobungcweti akuchazi kabusha lokho okungenzeka kuphela kodwa nalokho okulindelekile emhlabeni wokukhiqiza ngokunemba.

Isikhathi sokuthumela: Dec-20-2023